Professional EPS EPP ETPU Automatic machinery manufactuer.

Hangzhou Tekula Precision Machinery Co.,ltd

杭州特库拉精密机械有限公司

With a COMPLETE Automatic Solution

- Automatic quick mold change system

- Filming and surface texture process

- Optional automatic material handling,metal placement

- Intelligent IoT, Smart Factory builder

- Built-in thermal insulation mold cavity and PID energy management

- PID directly control,10-30% consumption reduced

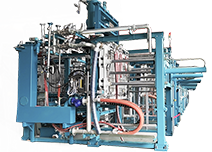

we have patented tech on machine energy saving process for EPS piece molding. the traditional energy utililization of EPS molding process is inefficient,most of the energy is lose in the air. we could maximize energy utilization by apply a in-built insulated steam chamber with new polymer material, so the EPS molds won't have to be heated and cooled thoroughly again and again, and could prevent heat loses in the air, and we have PID directly control for energy input for precise control of temperature and pressure for EPS molding process, about 10-30% energy could be saved in this way.

| Example regular EPS package production | ALESSIO/TEKULA | Regular EPS machine | Tested results |

|---|---|---|---|

| Pressure control | PID direct precise control | balancing valve + pressure regulator/PID indirect | NAN |

| EPS Molding pressure control | 1bar below | 1~2.5bar | Wasted steam |

| Insulated chamber | Applied in entire EPS fixed and mobile mold | No application around the outter side of the EPS mold | 3-5℃ lower in the external part of chamber than regular EPS machine |

| Steam consumption | 7-5 tons/per ton of EPS | 10-7 tons/per ton of EPS | More than 10-30% improved than regular EPS machine |

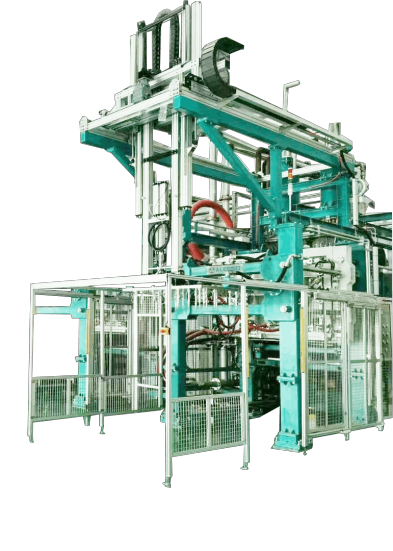

Automatic quick mold change system for EPS machine:quick connection for material supply with hydraulic mold locking device,patented hydraulic locking plier and quick connecting port,the pre-assembled mold would be connected with filling gun,water piping within just 2-5 minutes simply by just pressing one button,machine could resume to production within 5 minutes,it's a inavitable trend for EPS molding machine to go from semi-automatic,automatic machine with manual mold changing,semi automatic mold changing to full automatic mold changing.

Compare between Automatic QMC (quick mold change) system for EPS molding machine and regular machine

| 40 sets of EPS molding machine for a large-scale production | ALESSIO/TEKULA ALESSIO Automatic EPS QMC machine | Regular EPS machine | Tested results |

|---|---|---|---|

| Mold changing method | QMC | Semi-automatic/Manual regular | Short machine down time、less laborious job |

| Time for resume to production | 2-5miutes | 30-45minutes/1.5-2hours | Longer machine downtime |

| Shut down time in total | 4h | 25h/100h | Based on 50 molds changed on 40 sets of machine |

| Ratio of EPS production time lose | 0.38% | 2.27%/9.08% | more than 2% higher production ratio, equals extra one EPS machine |

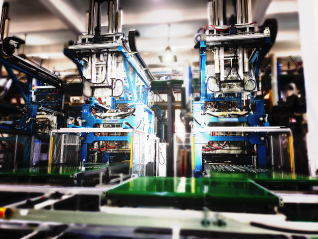

ALESSIO Automation & Handling Systems Processes. Costs. Optimization.

- Process optimization

- Improved product quality

- Increase in throughputs

- Reduction of waste

- Digital data collection

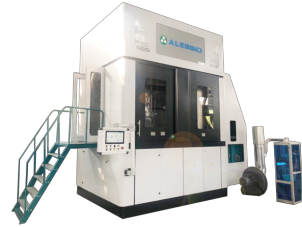

Alessio Smart Pre-expander

- Germany high precision weighing sensor can ensure the accuracy of raw material weighing and density monitoring

- Automatic density weighting and feedback system

- Double vacuum curing chamber, raw materials can obtain longer vacuum time compared to single vacuum chamber, and greatly reduce the number of silos

- German SPECK efficient vacuum pump

- German Siemens Digital Proportional steam control, frequency conversion variable precision speed control

Alessio efficient central vacuum system

- Efficient central vacuum system with automatic feedback and automatic control

- Due to the large condenser, the working environment of the vacuum pump is greatly improved

- Monitoring control, status monitoring

- Various fault alarm and operation protection functions

- High-efficient German SPECK vacuum pump

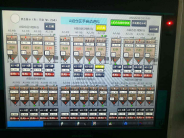

Alessio smart automatic EPS silos for molding machine

The automated centralized feeding system PMF series originated from advanced European design concepts, and can be used with PE-1.3VDA vacuum EPS pre-expander to maximize foamed EPS beads output. Among our series, the PMF-30 has a daily maximum output of 16 tons of foamed EPS raw materials and is equipped with a group of branch silos , A total of 30 silos, which can provide 12 to 24 hours of aging time, supply to 13 sets of EPS machine, it equips with valve switching system for material feeding zone supply. It is available for the precise control for multiple densities in a single zone to ensure each aging time; the available density range is 15-50 g/l; and BUS communication can be established; no manual intervention is required, providing with unmanned automatic raw material conveying system for EPS molding machine.

Intelligent software control system, based on the classic selection comparison method C++ programming framework, to ensure automatic selection of the optimal aged silo EPS raw material output at the current time period for molding machine, optional Siemens PLC control system, to ensure stable and reliable system intelligent control under harsh working conditions.

optional modular configuration mode to facilitate later expansion and upgrade, optional Internet of Things data backup interface for data access of the factory-level management system, and optional expandable display operating system to achieve local two-operation control which contribute to part of EPS automatic production line

The EPS silo feeding system adopts a centralized feeding program that is jointly controlled with the EPS pre-expander to automatically refill the corresponding density of the raw material silo; through the set pre-expansion time, the supply sequence of the raw material silo is controlled, so that the current used EPS material is always the one with the longest aged hours, and at the same time avoid manual mixing of EPS raw material silos which helps to ensure a stable and precise feeding for EPS molding machine

浙ICP备19035499号-1

浙公网安备33011302000335号

浙公网安备33011302000335号